Discussing Some Benefits of Considering Innovative Mould Works

- novelmouldcom

- Feb 9, 2021

- 2 min read

Aluminum actually more than ever has a significant place in the production moulds. When a fact is considering, Aluminum is less costly than P-20 tool steel – a substance of preference for high volume parts – & an aluminum mold could run cycle times 20 to 30 percent quicker than the steel. In the present automotive economic environment, a lot of OEM’s are telling their professional suppliers to switch to aluminum where feasible. Innovative Mould Works is all time demanding and appreciating.

Selecting the appropriate Aluminum for the Production Molds

When comparing with the P-20 steel,

Aluminum is considered 4 to 5 times better in terms of thermal heat transfer. By the better thermal conductivity, the position, as well as a number of water lines, is a lesser amount critical, facilitating for the placement of supplementary ejector pins where required.

Aluminum has established productivity enhancement of around 20 to 30% in cycle time savings.

Aluminum doesn't need to be sent out for stress relieving or heat treating. All this is carried out during the manufacturing procedure.

Aluminum has exceptional machining as well as polishing characteristics. By several high strength and effective aluminum alloys, ratings of machining are as high as 8 times quicker than the steel.

Each of the aluminum alloys is not made equal. For the production molds, we greatly suggest QC-10, a perfect high strength, heat-cured wrought aluminum alloy appropriate mold material.

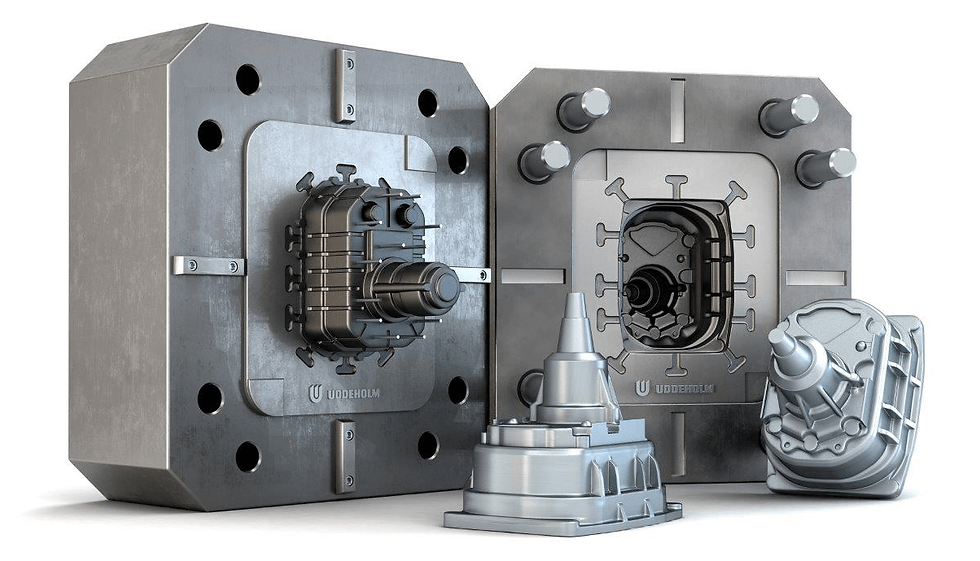

The MOLD Design:

At the time of designing a production aluminum mould and performing innovative mould works, several factors are required to be addressed for a flourishing mold. Is the resin favorable for the aluminum? What is the quantity? What is actually the part geometry of the portion to get molded? What is the preferred cycle time? How much time does the mold require to last? Such factors are allot same as the ones designers look at during the phase of designing a P-20 mold. By our aluminum tools, we will utilize a support frame that includes steel support pillars to build a mold that has all the thermal advantages of aluminum suited well with the sturdiness of a steel mold. The utilization of these support pillars keeps away from the prospect of over clamping the mold as well as crushing the parting line. Moreover, aluminum molding tools could be textured.

The Best Quality Aluminum tools ought to be treated with a little more care in comparison to the steel tools. They could be damaged with unnecessary clamp pressure, too much injection pressure, or through removing stuck parts by a sharp object or screwdriver. There should be a culture in the molding shop which is compatible and well suited with the aluminum tools. The shops, as well as companies that are making use of them, are reaping the advantages.

Novel Mould is here with the most advanced and best innovative mold works. We, anybody, talk about the best quality as well as services, they talk about the Novel Mould. Contact us now if you have any queries.

Comments